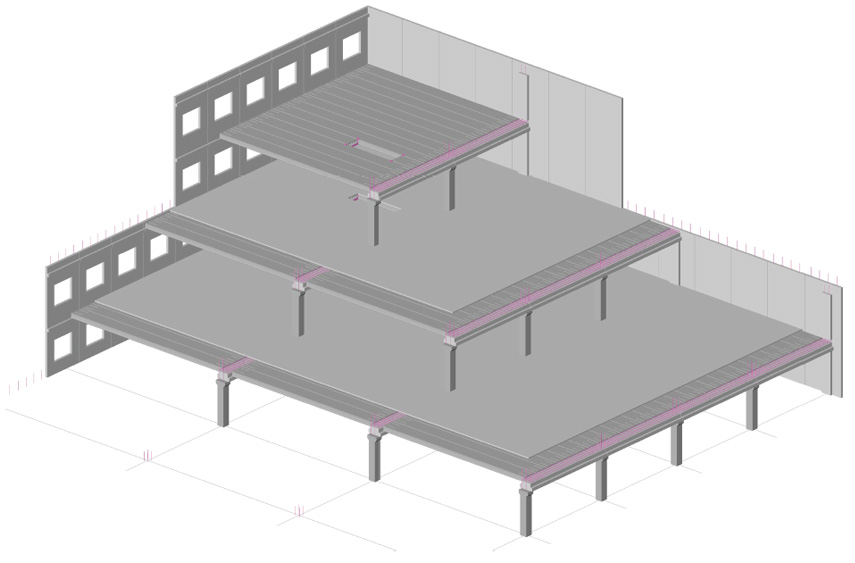

Precast Concrete Structures

Westkon Precast is well renowned for being able to provide precast products to the construction industry to industry leading quality and reliability. However, it is Westkon’s control over the design and installation of full precast structures (from the in-service design, erection design as well as on-site installation and final delivery) that sets them apart from others.

Precast concrete structures offer numerous advantages, primarily focused on design efficiency, speed of construction, long spans, durability, and cost-effectiveness.

Below is a more detailed look at the benefits of a precast structure:

Design Flexibility:

Due to Westkon’s flexible production facility, the various precast elements that make up a precast structure can be designed to suit almost any project requirement. This results in elements that can be produced in various shapes, sizes, and finishes, offering architects and designers significant creative freedom. It also allows freedom in the ability to integrated with other building systems and materials.

Speed of Construction:

Precast elements are manufactured off-site in a controlled environment, allowing for concurrent on-site and off-site work. This significantly reduces the overall construction program compared to traditional methods. But also, due to the significant reduction in temporary propping, allows for following trades to commence following works earlier.

Quality Control:

Production in a factory setting allows for precise control over material quality, curing, and inspections, resulting in a more consistent and higher-quality product.

Durability and Strength:

Precast concrete is known for its inherent strength and durability, resisting weathering, fire, and other environmental factors. It’s also resistant to rot, rust, and degradation, minimising maintenance needs over the structure’s life.

Cost Savings:

The reduced construction time translates to lower labour costs and less on-site material handling, leading to overall project cost savings. The long-term durability of precast structures also reduces long term maintenance expenses.

Reduced On-Site Waste:

Precast construction significantly reduces on-site waste, contributing to a cleaner and safer construction site.

Sustainability:

Precast concrete can incorporate recycled materials and is itself recyclable, making it an environmentally friendly option. Hollowcore planks, due to the manufacturing method and structurally efficient cross section, use significantly less material than a solid equivalent (~30-50% less concrete). This combined with the reduced cement in the zero slump concrete used for the hollowcore production (~25-30% cement reduction) results in a total of 40-60% less cement required.

Safety:

Precast construction reduces the need for extensive scaffolding and minimises on-site material handling, creating a safer working environment.

Resistance to Environmental Factors:

Precast concrete is not flammable and has a greater resistance to fire than most other materials. This along with its benefits with evening out extreme temperatures, and other harsh environmental conditions, make it a logical choice for various climates and locations.

Acoustic and Thermal Performance:

Precast concrete provides a significant benefit in having a high thermal mass as well as good sound insulation properties, contributing to a more comfortable and energy-efficient building.